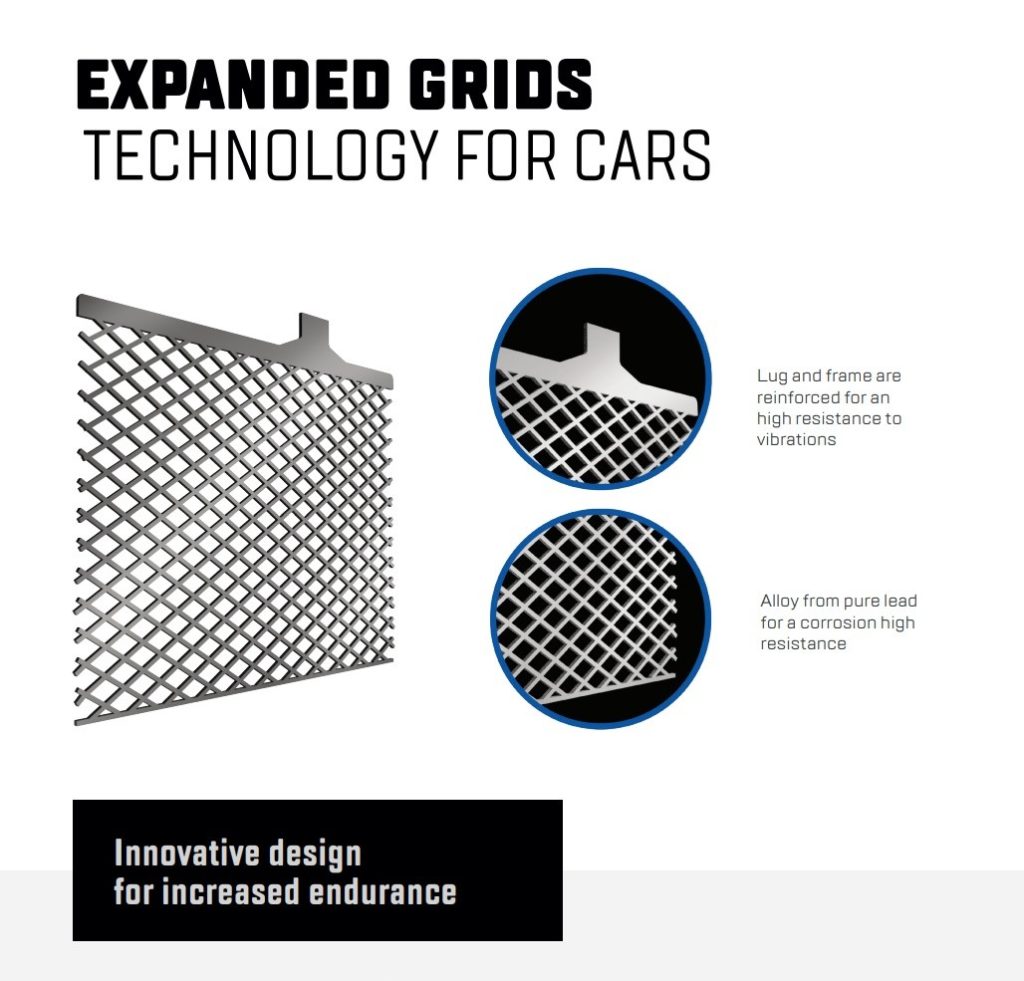

The wet charged series is made with flat Pb/Ca plates of increased thickness to better withstand the effect of cycles (duration) over time, in line with the new energy needs of cars. This is possible thanks to the innovative design of the grid, which allows an excellent distribution of the current in the discharging and charging phases. The irregular diamond shaped grid, which is narrower at the top of the grid and wider at the bottom, facilitates the chemical/electric reaction in the discharging and re-charging phases, thus enhancing starting performance, without sacrificing durability (life-cycle).

This is possible due to the widened cross points of at the geometric intersections. The alloy is manufactured using primary lead (99.99%) with calcium/aluminium and tin, so it is possible to support the concept of ZERO MAINTENANCE with very low self-discharge (temp. 25/30°C), in addition excellent resistance to corrosion.

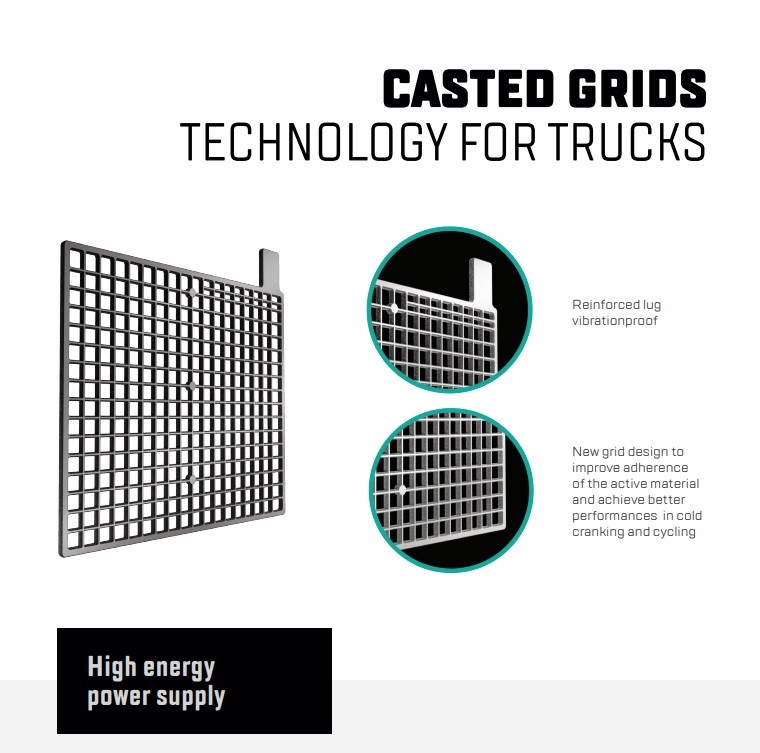

The recent technological developments related to the manufacturing of the elements used for truck starter batteries, in specific grids, means that many manufacturers have chosen the expanded plates or punching. In the commercial vehicle sector the massive presence of electronics, electrical accessories, hydraulic and satellite systems, etc. means batteries not only start properly but, above all, that they must ensure a high energy supply as support even when the engine is switched off, particularly with E5-E6 engines. CARRAY has always used casted grid technology, which is more robust and suitable to perform this dual task (starter and prolonged discharge). New grids (pos. and neg.) were made in view of the new requirements, with a new design studied to allow optimal performance of repeated discharges and recharges, as well as remarkable starting performance. More attention was focused on the thickness of the plate, in order to increase the nominal capacity (AH) of the battery. As is easy to understand, when analysing heavy vehicles used for transportation, agriculture, construction etc., we find ourselves faced with the usual problems of vibrations and bumps present due to the uneven ground they have to cover. Specifically, the casted grid offers more robustness and reliability, without prejudicing devices for blocking elements, inside each cell of the box, which stop the fall of the active material on the plate. The alloy is manufactured using primary lead (99.99%) whether they are calcium (Ca) plates or those with a low content of antimony (Sb), which supports the ZERO MAINTENANCE concept and very low self-discharge (temp. 25/30°C), in addition to excellent corrosion resistance.

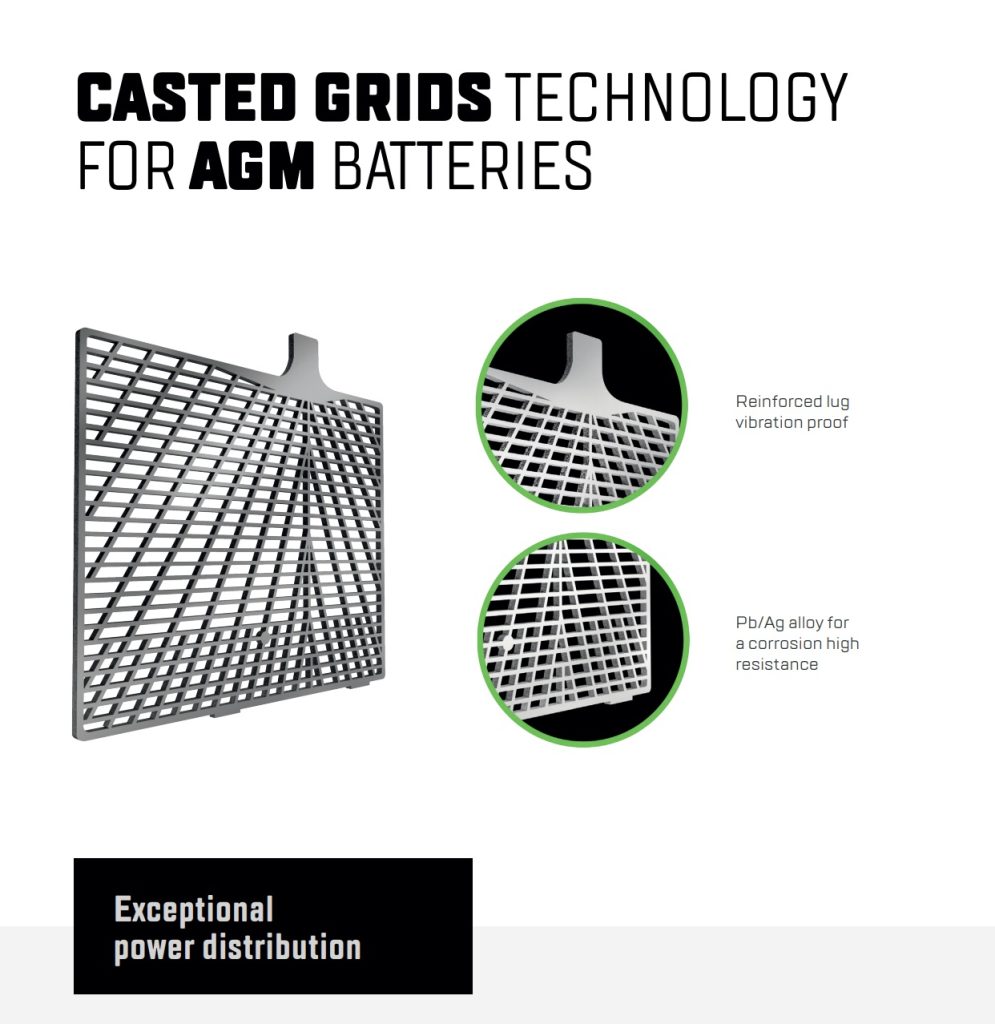

This wet charged series is made of casted Pb/Ca plates, in line with the new energy needs of cars equipped with the Start & Stop system. This is possible thanks to the innovative design of the grid, which allows exceptional power distribution during charging and discharging, ensuring a duration (cycles) higher than the energy of specific cars. The alloy is made with the use of primary lead (99.99%) with calcium/silver, for better charging, and therefore making them MAINTENANCE FREE, as well as having a very low self-discharge (temp. 25/30°C), in addition to exceptional corrosion resistance.

CERTIFICATIONS

UNI ISO 45001

UNI EN ISO 9001

UNI EN ISO 14001

OHSAS 18001